Right now, the world is seeing the equivalent of what could only be termed a gold rush to build battery factories, and these plants will be able to produce many more cells than the global economy could conceivably need or use in the coming decade. That warning comes from a new report from BloombergNEF, but the writing on the wall has been clear for the past 18 to 24 months.

By the end of 2025, the global battery industry will be able to produce more than five times the number of cells needed by the world that year, according to BloombergNEF’s Electric Vehicle Outlook 2024.

“This is good news for automakers and EV buyers,” the report asserts. The glut, however, “marks a challenging time ahead for new entrants to the battery industry,” the report goes on to say in a gross understatement.

Existing firms could find themselves out of business if prices drop below sustainable levels. Only time will tell if building so many factories was the right business decision.

Currently, oversupply is most acute in China, where manufacturing capacity is expected to exceed annual battery demand for at least the remainder of the current decade.

Meanwhile, prices for new and used EVs alike are falling, and automakers such as Ford are scaling back their EV expansion plans in the middle of a price war for battery-electric cars and trucks.

Alternative battery technologies are also being investigated and tested on a daily basis. Lithium iron phosphate (LFP) batteries are rising in popularity, especially in China, and their materials costs are significantly lower than those of lithium nickel manganese cobalt (NMC) batteries.

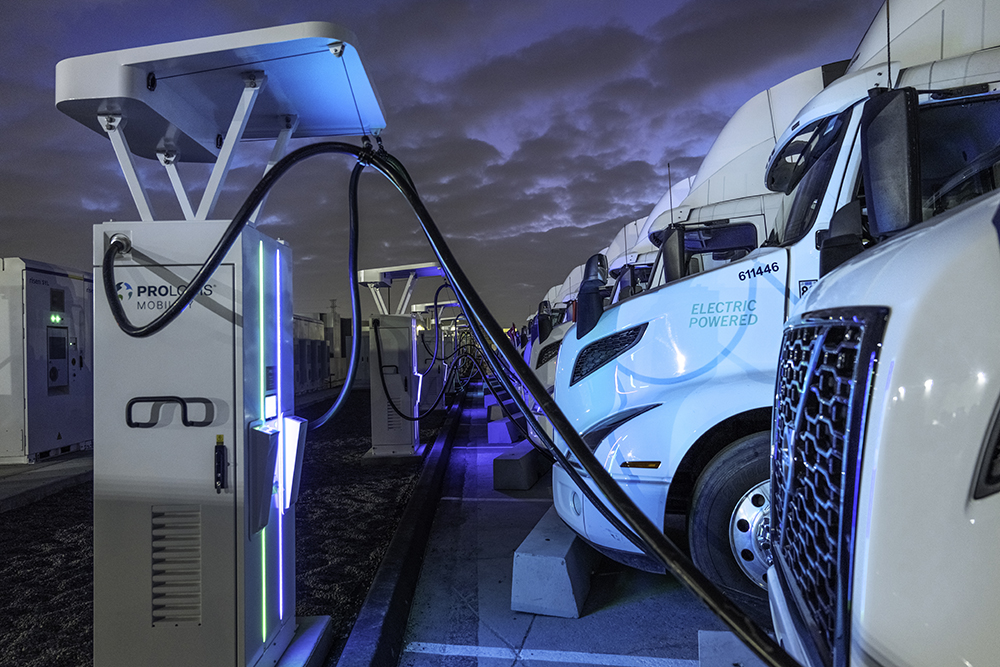

It is true, of course, that the demand for lithium-ion cells is growing fast as industrial vehicle and automobile companies electrify their fleets—and electrified vehicles are only part of the story.

The other piece of the puzzle is stationary storage. Power companies are installing giant batteries for a variety of purposes. They are used to soak up excess solar power during the day and store it for nighttime use, supplying power that previously was generated by burning fossil fuels, as well as to stabilize power grids.

While the battery industry may be suffering from an abundance of riches at the moment, there are few if any guardrails out there to prevent it from collapsing under its own weight if its executives don’t see what’s coming around the curve.

In 2015, Bloomberg News reported that no other US business had declined as much in the preceding 15 years as one-hour photo labs. By that year, there were just 190 stores still operating in the country, down from 7,600 one-hour labs and 14,700 mini-labs inside other shops in 2000. If you want to take your film for processing to one of the remaining Fotomat huts, be forewarned that most have become drive-through coffee shops.

Source: Bloomberg

[NW1]Could argue lithium-iron-phosphate are traditional lithium-ion batteries as they preceded lithium-nickel-manganese-cobalt – the industry is returning to them.

[JS2]I listed this as the source because it gave me the idea plus I didn’t know whether you use Source on non-product announcement stories. Better safe than sorry.

from Charged EVs https://ift.tt/Vyl5puT