Intensive testing of EV batteries is crucial. It is not only about the test; it is about how to test! EV manufacturers, suppliers, and test facilities must use their battery test labs equipment to ensure fast and efficient battery development.

In this free webinar, presented by Keysight at our Spring Virtual Conference on EV Engineering, we will highlight ways to improve efficiency in designing and operating your battery test lab and getting insights into the cell and battery pack faster. Join in and learn more about how we at Keysight approach innovations in battery tests to face future test challenges.

Other sessions at our Spring Virtual Conference include:

The Role Of Testing In Ensuring The Functionality, Quality And Reliability Of Battery Management Systems

Testing plays a vital role in ensuring the quality and reliability of battery management systems (BMS) during the design validation and manufacture stages. The purpose of testing is to verify that the BMS meets the specified requirements and functions as intended under various operating conditions.

During the design validation stage, testing is used to evaluate the performance, safety, and reliability of the BMS design and its controlling firmware. This includes thermal and environmental testing, which verify that the BMS can operate within the specified temperature and humidity ranges, and electromagnetic compatibility testing, which verifies that the BMS does not generate electromagnetic interference that could affect other electronic systems and is not subject to electromagnetic interference from other sources. As part of a hardware-in-the-loop (HIL) simulation test strategy, the BMS is tested for reactions to faulty signals.

During the manufacturing stage, testing ensures that each BMS unit is built to the correct specifications and is free from defects. This includes functional testing, which verifies that the BMS operates as intended, and quality control testing, which verifies that the BMS meets the specified quality standards.

By performing these tests, the manufacturer can identify and correct any issues before the BMS is put into service, ensuring its high quality and reliability.

Join this session, presented by Pickering Interfaces, to learn how industry-standard, modular PXI-based switch and simulation products can be used in BMS functional testing to simulate correct battery voltage, current and temperature readings, as well as HIL and fault insertion testing to verify correct BMS operation under a range of real-world conditions and fix potential issues before the systems are deployed in the field.

Other sessions at our Spring Virtual Conference include:

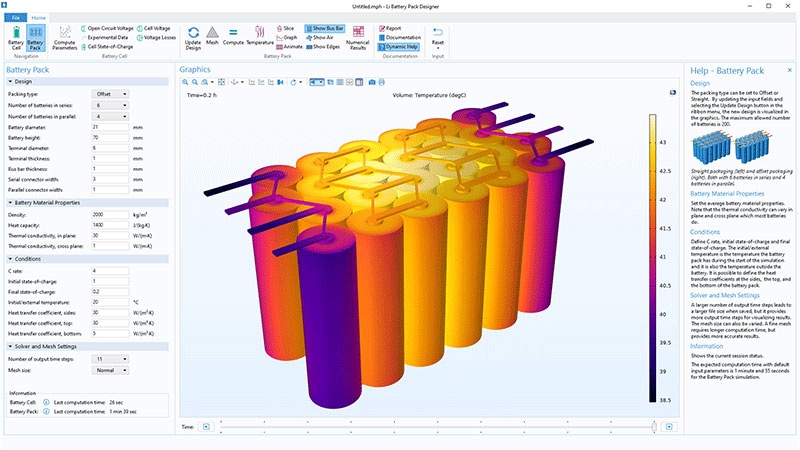

Battery Modeling with COMSOL Multiphysics

Detailed understanding of battery technology and the underlying physics processes is necessary to design high-performance, durable, and safe batteries. Physics-based modeling is being used for building accurate simulations of batteries, incorporating different aspects through predefined physics-based interfaces, from detailed structures in a battery’s porous electrode to the battery pack scale, including thermal management systems.

In this webinar, we will discuss and demonstrate how COMSOL Multiphysics® and the Battery Design Module provide different features and functionalities for battery design and analysis, which can help in the development of the next generation of batteries and facilitate the integration of these batteries into final electrical devices.

See the full session list for the Spring Virtual Conference on EV Engineering here.

Broadcast live April 17 – 20, 2023, the conference content will span the EV engineering supply chain and ecosystem, including motor and power electronics design and manufacturing, cell development, battery systems, testing, powertrains, thermal management, circuit protection, wire and cable, EMI/EMC and more.

from Charged EVs https://ift.tt/YZ9nRXh

No comments:

Post a Comment