Reducing the carbon footprint and optimizing thermal cooling are paramount in modern manufacturing and have become significant criteria for selection and deployment of automated test equipment. In addition, budget constraints could be circumvented by the use of multi-purpose instrumentation. Last but not least, replenishing dissipated power to the grid will save a substantial amount of money annually if set up properly. More than ever, when it comes to selecting power conversion test equipment, design and test engineers need both technical advantages and eco-friendly benefits.

The abovementioned items can all be addressed by replacing traditional power supplies and loads with modern bidirectional and regenerative power conversion test equipment. Instruments designed for high power and renewable applications are currently available in the market from various sources. Parallel connections of multiple instruments in a rack offer Megawatt capabilities, depending upon the vendor specifications.

Today’s power conversion automated equipment (ATE) should be designed to fit your design validation testing (DVT) requirements in the lab and high-speed functional testing in the production line all while reducing wasted energy. From the Electric Vehicle Supply Equipment (EVSE) to EV power components to the battery, properly engineered automated test equipment will maximize your time, improve your validation process, increase your throughput, and reduce operational costs.

Bidirectional DC Power Technology

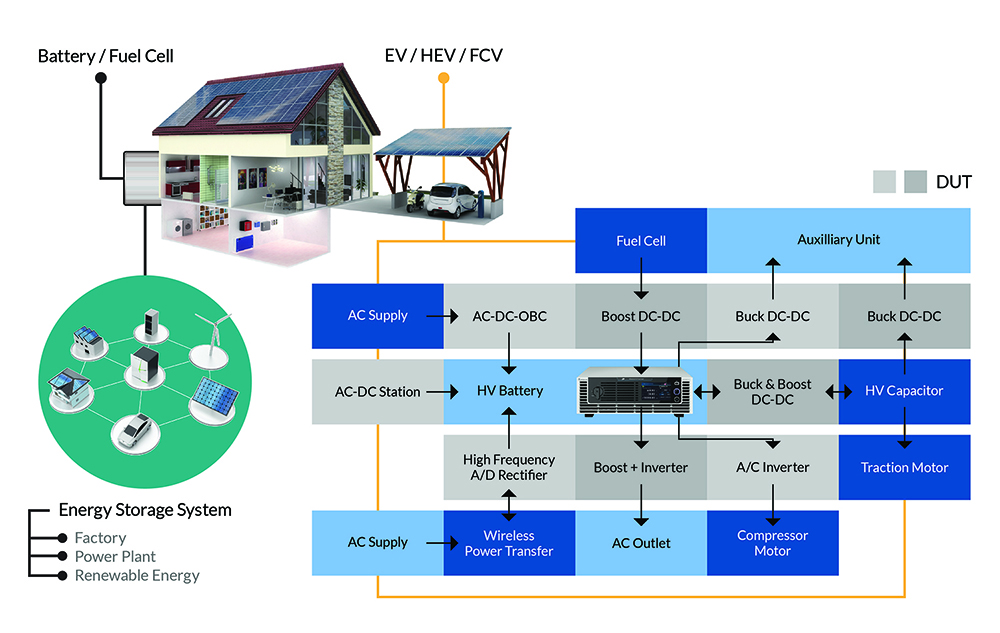

Bidirectional technology has both power (source) and load (sink) characteristics, two quadrant operation, and allows feedback of the power from the DUT. They can be used for testing renewable energy power systems including PV/storage hybrid inverters, power conversion systems (PCS), battery charge/discharge, and as a battery simulator. Bidirectional power supplies are also a fit for testing power components used in electric vehicles.

Chroma 62000D Bidirectional DC Power Supplies, for example, are pre-compliant with LV123 and LV148 standards making it suitable for EV component testing, including bidirectional on-board chargers (BOBC), bidirectional DC converters, DC-AC motor drivers, and power conversion simulation tests in both directions. Its high-speed CV dynamic response slope, with control up to 180V/ms, enables efficient electrical characteristics testing in line with vehicle guidelines.

62000D models offer power ratings of 6kW, 12kW, 18kW, 36kW, and 45kW with parallel and series operation capabilities. Voltage ranges span from 0 to 100V/600V/1200V/1800V. With its four times auto-ranging operation range, the 62000D can cover a wide range of low voltage/high current and high voltage/low current scenarios for devices under test. This consolidation of multiple DC power supplies into a single 62000D unit brings space and cost savings when integrated into standard ATE systems or labs. Additionally, the 62000D boasts a high-speed transient response of less than 1.5ms, enabling seamless and rapid current conversion between the two quadrants.

Most commercially available bidirectional power supplies, including Chroma, can operate with 90% or better efficiency, meaning that only 10% of test power is lost as heat or wasted energy. High efficiency translates into lower operating costs when a bidirectional power supply is used rather than a separate power supply and load at a given power level. Bidirectional power supplies can be programmed for different modes of operation, including constant voltage (CV), constant current (CC), constant power (CP), and constant resistance (CR).

regenerative Grid Simulation

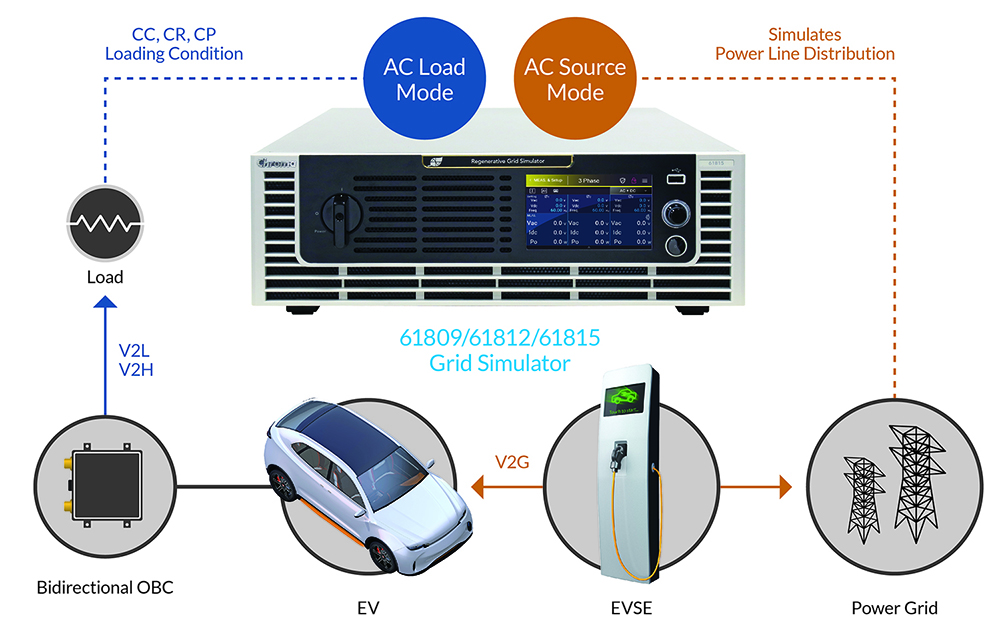

Regenerative Grid Simulators are a full 4 quadrant, fully regenerative AC power source that emulates grid characteristics for testing to standards such as IEEE 1547 / IEC 61000-3-15 / IEC 62116. The grid simulator’s power can both “sink to” and “source from” the UUT seamlessly to test grid-connected devices, including PV inverters, online UPSs, Smart Grid, and EV related test applications, including Vehicle to Grid (V2G) and Energy Storage Systems (ESS).

In addition to supplying clean, precise, and stable AC voltage, Chroma 61800 Regenerative Grid Simulators can simulate various types of distorted voltage waveforms and transient conditions required for product validation testing in the lab. The power generated by the DUT during the test can be fed back to the grid, rather than dissipated as heat, which addresses environment concerns and lowers the cost of operation. With this capability, these instruments can be applied to applications in green energy, such as PV inverters, energy storage systems (ESS), power conditioning systems (PCS), micro-grids, power hardware-in-the-loop (PHIL), electric vehicle supply equipment (EVSE), on-board charger (OBC) and bidirectional on-board chargers (BOBC), etc.

In addition, Chroma 61800 Regenerative Grid Simulators feature a regenerative AC Load Function that allows a single unit to function as either an AC Load or an AC Source. This function is intended but not limited to EVSE charging station, hybrid PV inverter, UPS, and bidirectional on-board charger test applications. The 61800 series has power ranges from 9kVA up to 105kVA, is single-and three-phase selectable, and supports up to 3 units in parallel.

regenerative Battery module and pack cyclers

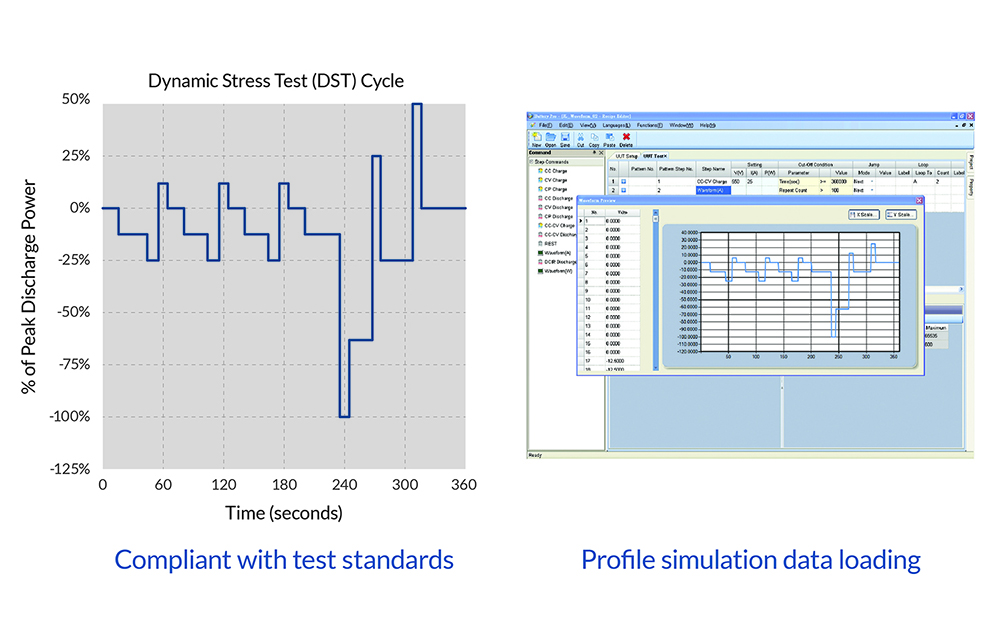

When it comes to EV battery charge and discharge test systems, the minimal ticket to entry is high power with regenerative capabilities. An advanced system would offer dynamic profile simulation and battery simulation, as well as added safety features. System software should provide flexible test editing functions, independent channel testing capabilities, and assure high safety and stability throughout the testing process.

The Chroma 17040E Regenerative Battery Cycler is a state-of-the-art high-power battery test system currently capable of handling voltages up to 1700V, currents up to 4800A, and power up to 1.2MW. The 17040E is available in four voltage and current ranges with auto ranging, high accuracy current/voltage measurement (±0.05%FS/±0.02%FS), 2ms current slew rate, and 1ms data acquisition.

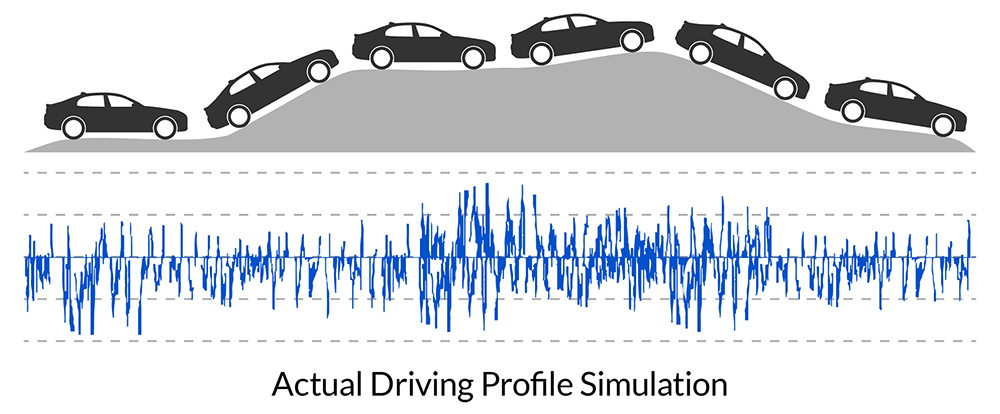

The dynamic profile simulation function of the Chroma 17040E allows users to load battery waveforms based on specific drive profiles in either current or power mode. This feature ensures compliance with NEDC/FUDS requirements and facilitates accurate testing in line with international test standards, including ISO, IEC, UL, and GB/T.

The battery simulation mode enables testing of battery connected devices. When a connected device is under development, the 17040E can simulate the battery to verify if the device is functioning as designed. In addition, the 17040E can control the SOC status of different batteries. Users can simply upload required battery curves to test the DUT for charge and discharge status.

Safety is a top priority when it comes to battery testing. The 17040E incorporates advanced safety features such as Over Voltage Protection, Over Current Protection, Over Temperature Protection, and external parameter detection. These measures ensure protected charge/discharge testing and prevent any interruption or loss of test data, even in the event of a power failure.

So why adopt this technology?

So why adopt this technology? Bidirectional and Regenerative AC and DC power sources and loads can simulate real-world operating environments more closely. They also reduce the number of instruments needed in your test lab and reduce energy usage over traditional test equipment, which can only discharge power in the form of heat. When used widely in high-power applications such as EVSE testing or battery cycling, this testing technology saves electricity costs and contributes to reducing carbon footprints significantly worldwide.

Thus, when creating a test environment, it is key to recognize the opportunity of addressing both technical advantages and eco-friendly benefits of the test equipment provider. Taking these benefits into consideration at the start of the project will further enhance the ROI payback timeframe.

from Charged EVs https://ift.tt/4r5DPCW

No comments:

Post a Comment