In a recent Charged webinar, Dave Schaller, Industry Engagement Director at the North American Council for Freight Efficiency (NACFE) presented 10 electric truck case studies—real-world examples of how companies are benefitting from deploying EVs.

The 10 examples cover a wide variety of use cases, including one that’s often cited as the perfect use case for EVs: terminal tractors. These specialty vehicles, also known as drayage vehicles or yard goats, move cargo around within and between port facilities and logistics centers.

“Terminal tractors are unique vehicles,” says Dave Schaller. “They are the first vehicle that all fleets should consider electrifying.”

Terminal tractors are unique vehicles. They are the first vehicle that all fleets should consider electrifying.

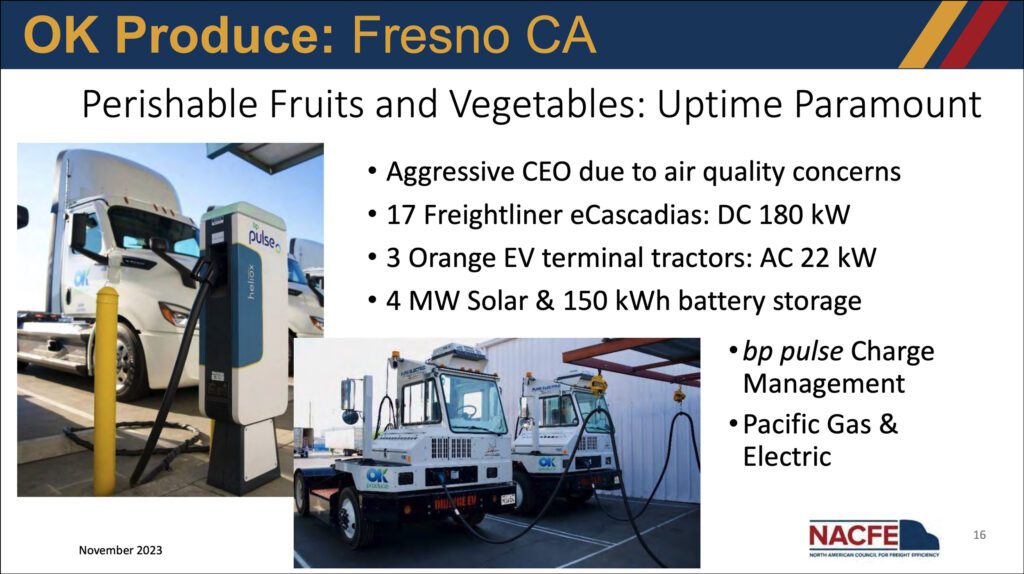

OK Produce in Fresno, California, delivers perishable fruits and vegetables, so uptime is critical. The company is moving forward aggressively with electrification, and part of its strategy is electrifying its drayage vehicles.

Dave Schaller explains some of the reasons that terminal tractors are at the top of the list of vehicles to electrify: “If you buy a new diesel terminal tractor with the current after-treatment systems on the exhaust, that after-treatment system wants to get hot to work properly with its filtering system. These trucks rarely go more than a quarter-mile around the facility, and half the time they’re moving an empty trailer, so there’s no real load on the engine most of the time, and the exhaust can’t get hot because the diesel engine isn’t working very hard.”

“It’s the perfect operation for a battery-electric vehicle,” Schaller continues. “If you’re one of those that has this insane range anxiety, what better than a Class 8 truck that doesn’t leave your yard? How can you have range anxiety when you can virtually always see the charging station? Many fleets that are starting to use electric terminal tractors position them near where the drivers go in and out of the facilities, so when they stop for a break, they can plug in the vehicle and opportunity-charge it.”

OK Produce has 17 Freightliner eCascadias, which use 180 kW DC fast chargers, and 3 Orange EV terminal tractors, which use Level 2 charging at 22 kW. The company has 4 MW of solar and 150 kWh of battery storage at its facility. The bp pulse charge management system makes all the components work together, supported by local utility Pacific Gas & Electric.

Source: Charged webinars

from Charged EVs https://ift.tt/SGgi1Rs

No comments:

Post a Comment