Automotive company Sumitomo Rubber has developed a new simulation technique called Tire Aerodynamic Simulation, which is used in the process of tire development to visualize the airflow around the tire of a running vehicle

This simulation will help to develop a tire shape that optimizes aerodynamic performance and contributes to lowering the electricity consumption in a next-generation EV tire to be launched in 2027. In EVs, which cause almost no energy loss due to heat, around 34% to 37% of the energy loss is attributed to the tires, if rolling resistance is included with air resistance.

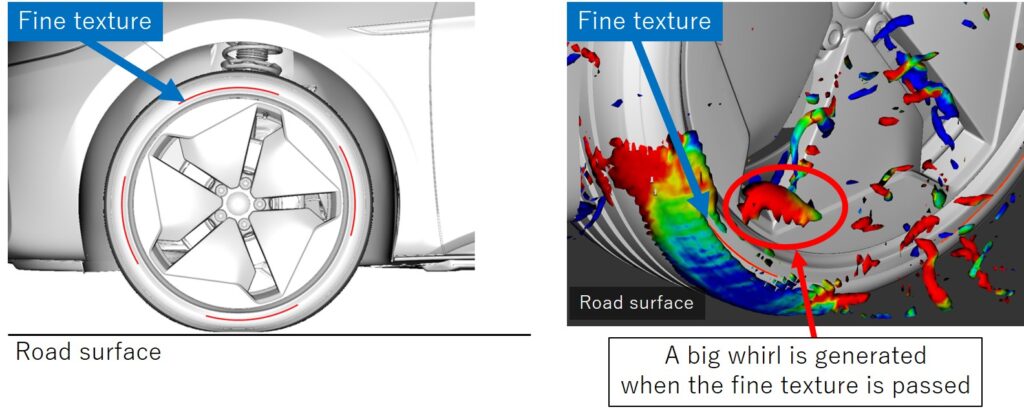

Also, the company claims to have developed a new simulation technique that changes the shapes of the lettering and fine texture on the sidewall while they are rotating with the pattern. In comparison with the results of a wind tunnel experiment, which was conducted with an actual vehicle to confirm the accuracy of the simulation, the EV tire with a decreased airflow trend behind the tire and less unevenness on the sidewall showed lower air resistance values than a standard tire.

“Adopting this technique yields improved tire performance with maximized aerodynamic characteristics, leading to reduced aerodynamic drag and electricity consumption for an EV,” the company stated.

Source: Sumitomo Rubber

from Charged EVs https://ift.tt/C8PpNIK

No comments:

Post a Comment