Paris-based global aluminum products manufacturer Constellium has announced that its ALuminium Intensive Vehicle Enclosures (ALIVE) collaborative research project has achieved weight savings in its structural aluminum EV battery enclosures.

The project reduced the weight of the enclosures by between 12% and 35% compared to existing aluminium and steel OEM designs, while meeting or exceeding performance targets.

The £15-million project began in 2020 and was half-funded by government subsidies through the UK’s Advanced Propulsion Center. The lead partner was Constellium’s University Technology Center (UTC) at Brunel University London. The other industrial partners were BMW, EXPERT Technologies Group, Innoval Technology, Powdertech and Volvo. Two university technology partners were Brunel University London and the University of Warwick.

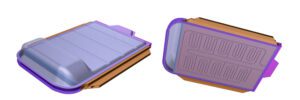

The goal of developing novel high-performance, lightweight and cost-efficient aluminium battery enclosure designs for the project’s OEM partners, BMW and Volvo, was pursued by investigating various joining and forming technologies in combination with Constellium’s high-strength alloys—Constellium HSA6 and Constellium HCA6—and by creating a full-scale battery enclosure prototyping line.

Several prototype enclosures were built that have passed rigorous testing for crash/side impact, bottom intrusion, acceleration, shock, vibration and leaks. Constellium researchers are now adapting the project’s design philosophies to other enclosure types, including chest battery packs for trucks and SUVs.

Source: Constellium

from Charged EVs https://ift.tt/5HQNF1Y

No comments:

Post a Comment