EMP Metals, a Canadian lithium exploration and development company, is conducting a direct lithium extraction (DLE) pilot at its facility in Saskatchewan.

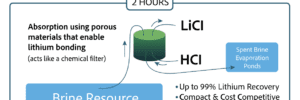

The facility has a DLE pilot skid from UK engineering technology firm Koch Technology Solutions (KTS), while Canadian lithium refining systems supplier Saltworks Technologies provided pre- and post-DLE systems and concentrate, refine and convert (CRC) technology to produce battery-grade lithium carbonate.

The geological brine was processed through the KTS Li-Pro pilot over 75 days, demonstrating a lithium recovery of greater than 97% and impurity rejection of greater than 99%. The DLE eluate has been delivered to Saltworks for processing through its Pilot 10 lithium refinery to convert it into a battery-grade lithium carbonate for delivery to offtake customers.

“The site pilot produced lithium concentrations in the DLE eluate exceeding 2,000 mg/L with a Li:TDS ratio greater than 0.1, almost non-detectable organics, low silica and steady performance improvements as the system was remotely optimized,” said Megan Low, VP of Lithium Process Solutions at Saltworks. “Li:TDS ratio is a key performance indicator. A ratio of 0.1 or higher is among top-performing DLE systems and is reflective of the high quality and clean Saskatchewan brine processed. This Li:TDS ratio will allow efficient downstream refining to battery-grade materials.”

Source: EMP Metals

from Charged EVs https://ift.tt/5d3y6QJ

No comments:

Post a Comment