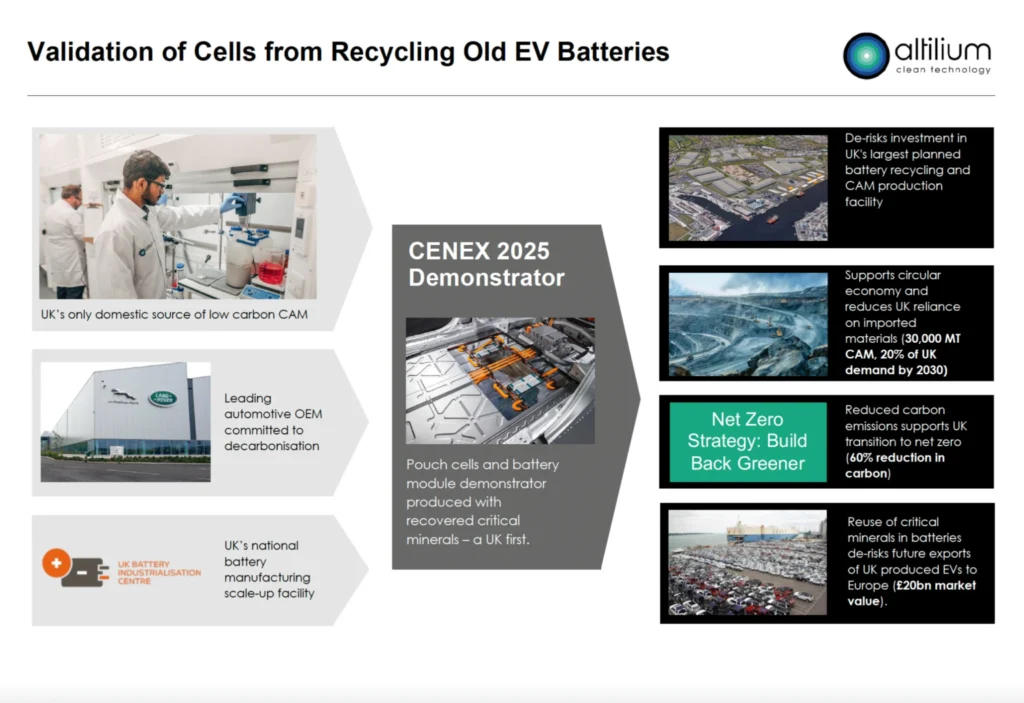

UK-based battery materials recycling company Altilium has announced a project to produce EV battery cells using cathode active materials recovered from end-of-life EV batteries and validate them for use in vehicles for UK-based luxury car manufacturer JLR.

The project is supported by the Advanced Propulsion Centre UK under the latest round of its Advanced Route to Market Demonstrator (ARMD) competition.

Altilium says its EcoCathode process, used to recover such materials as lithium, cobalt and nickel, results in a 60% reduction in carbon emissions by lessening the need for newly mined materials.

Battery production will take place at the UK’s national battery manufacturing scale-up facility, the UK Battery Industrialisation Centre (UKBIC), using recovered materials produced by Altilium in Devon at its mini-commercial ACT2 facility and its ACT1 pilot. JLR will conduct validation studies on the pouch cells at its battery testing facilities.

Altilium COO Christian Marston said, “By demonstrating that EV battery cells made from recovered materials can meet the rigorous standards of the automotive industry, we’re not only reducing the environmental impact of battery production but also supporting the UK’s efforts to build a more sustainable and resilient EV supply chain.”

Source: Altilium

from Charged EVs https://ift.tt/6imjkVs

No comments:

Post a Comment