Busbars are familiar components in just about any type of electrical equipment, and naturally they can be found in EVs and EV charging hardware. Not all busbars are alike—different requirements, dimensions and geometries have to be considered in the manufacturing process.

WAFIOS develops specialist machinery for the wire and tube processing industry, including machines that produce a broad range of busbar products. WAFIOS busbar machines can be adapted to the individual requirements of a production process, whether the application requires short or long busbars, complex busbars, or busbars with or without twisting.

The BMF series is particularly suited for the production of more compact busbars, such as those installed in vehicles that offer little space. The patented WAFIOS tool technology makes very tight radii with a thin profile possible, and the alignment of the busbar ends can be modified in a flexible way by twisting. The company’s patented rotary roller infeed unit, which is used in virtually all WAFIOS wire bending machines, is designed to offer maximum production speed.

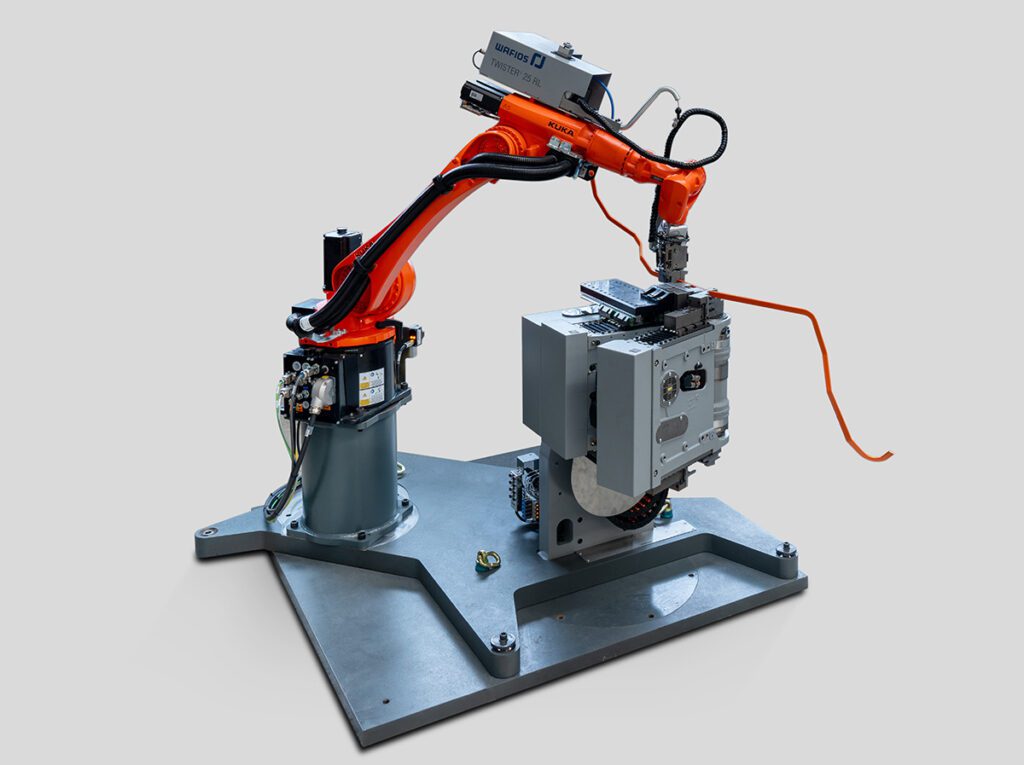

For the production of extra-long busbars with a large conductor cross-section, WAFIOS offers the TWISTER 25 and TWISTER 35. Originally intended for the tube-bending sector, the TWISTER has been adapted for e-mobility applications. These machines use the rotary-draw bending method to process busbar cross-sections of 300 mm² and lengths of up to 3,000 mm.

For its busbar bending machines, WAFIOS offers end-to-end automation solutions for additional or subsequent operations. These include punching various geometries, ultrasonic welding, feeding in and mounting stator connector parts, labelling the busbars and discharging them onto workpiece carriers or transport belts in the correct position. These features are designed to enable manufacturers to increase their productivity, improve quality and reduce the cost per piece.

“With automation solutions like EasyRobot, handling busbars is no problem. The operation of the robot is fully integrated into the bending machine,” says Jörg Eisele of the WAFIOS Executive Board.

Insulation stripping is an important step when processing busbars—the completed surface must be free from any residue of the PA 12 material. Insulation may be stripped by mechanical means or by using a laser. WAFIOS explains that mechanical insulation stripping ensures that any trace of the insulating material is removed, leaving no residue behind. A CO2 laser, in contrast, always leaves behind a layer in the micrometer range, which needs to be removed with brushes.

WAFIOS is seeing increased demand for mechanical insulation stripping. “Mechanical insulation stripping is a cost-effective alternative to the CO2 laser,” says Eisele. “It helps to reduce the cycle times involved in insulation stripping by 40 percent or more, which means a higher output rate from the entire machine system.”

The insulation stripping system in WAFIOS’s BMF 60 and BMF 90 busbar machines features seven axes and two milling units to enable maximum flexibility. The CNC insulation stripping device allows any combination of stripped sides to be produced at the busbar end, depending on the connection situation of the busbar. The insulation stripping device is integrated into the machine between the infeed and cutting unit.

Source: WAFIOS

from Charged EVs https://ift.tt/MZlqdnu

No comments:

Post a Comment