German machine tools and laser technology supplier TRUMPF has developed new laser applications for adhesive and coating preparation in battery production and for corrosion protection of aluminum components.

Coating or laminating battery cells before gluing them into modules or trays protects against short circuits and environmental influences, increasing the safety and service life of the battery cells, the company said. Before applying the coating and adhesive, manufacturers clean the cells and certain areas of the battery trays with short-pulse lasers, which hit the surface of the material without damaging the material itself.

To protect corrosion to car body components from milling, the laser homogenizes the surface by selectively remelting a few micrometers and then rapidly quenching it, making the aluminum components resistant to corrosion. In tests in which the parts processed in this way were sprayed with salt water for hours, they showed no signs of crevice corrosion, TRUMPF said.

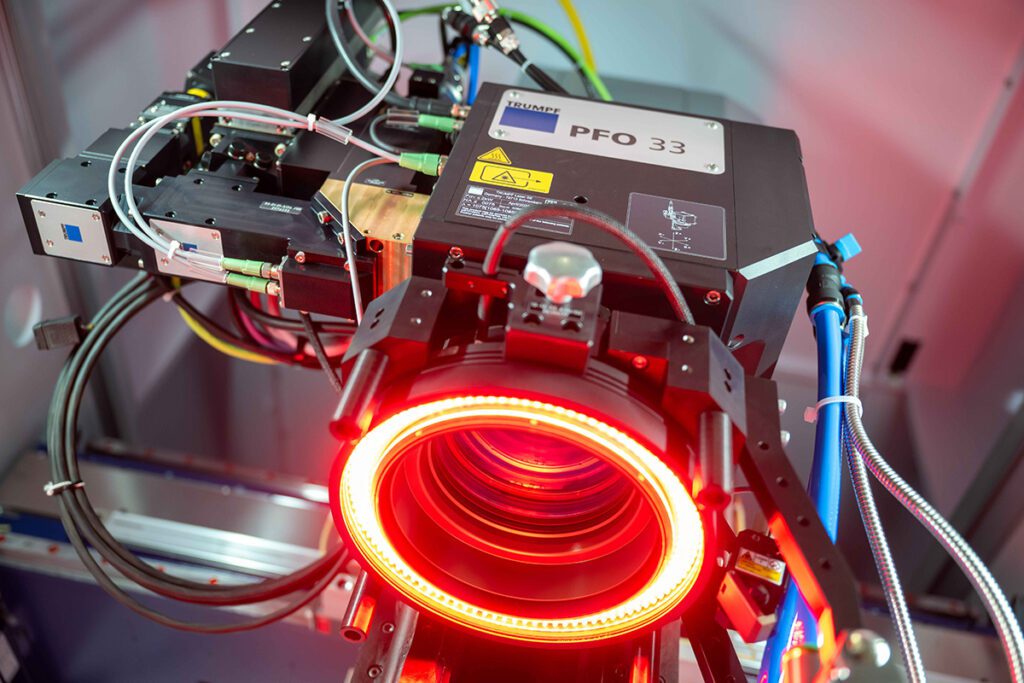

To process large surfaces, such as aluminum components, users employ the PFO33 scanner optics with a pulsed laser from TRUMPF’s TruMicro Series 7000. The PFO33 has mirrors that move the laser pulses across the component at speeds of up to several meters per second.

This enables short cycle times, which are crucial for automotive series production. Local extraction removes smoke, particles and aerosols that are produced during laser processing and could interfere with the machining process.

“Selective surface processing with lasers is a clean and fast alternative to chemical processes in the automotive industry, for example to achieve high adhesive strength for adhesives or coatings,” said Volkan Yavuz, responsible for laser surface processing at TRUMPF. “Our lasers reliably remove oils, rust, oxides and other residues, and ensure long-term stable adhesion of the coating and adhesive, without the use of aggressive chemicals or mechanical rubbing. This technology is not a dream of the future: it is used not only for gigacasting components, but also for housings for electric motors for electric cars.”

Source: TRUMPF

from Charged EVs https://ift.tt/CdgjYDM

No comments:

Post a Comment